2D Finite Element Analysis OF Aggregate Influence On Mechanical Properties Of Mortar Samples

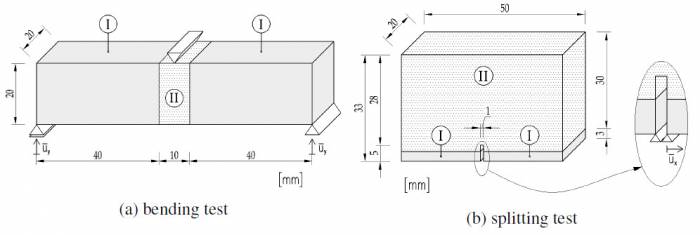

The simulations were focused on the investigation of aggregate shape and size influence on the bending strength evaluated from three-point bending tests, and fracture-mechanical properties evaluated from a series of splitting tests. The geometry of tested specimens is described in Figure below:

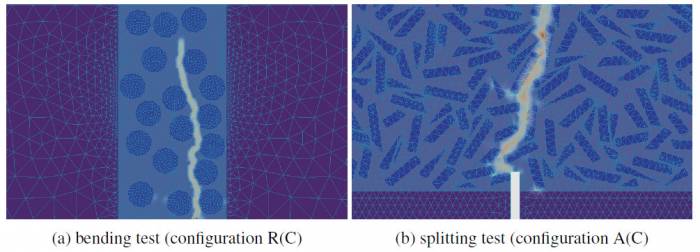

The conforming triangular finite element mesh was generated employing the capacities of the ANSYS software. The mesh density, which is coarse near supports in case three-point bending test and significantly finer in the expected crack location. The plane-stress numerical simulations were carried out in the OOFEM finite element code. An isotropic damage model with linear softening was assumed for the matrix phase, while the aggregates were modeled as isotropic elastic.

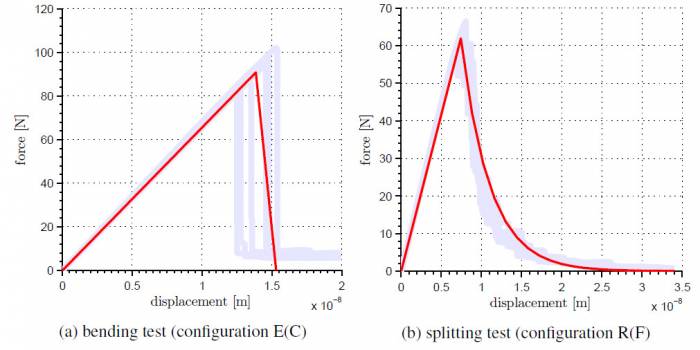

Six random distributions of a single aggregate shape and size were generated in order to obtain reliable data. The results were averaged within the individual configurations, providing a smooth force-displacement diagram.

The stress concentrations due to presence of angular particles resulted in a lower resistance of the specimens in three-point bending tests, which was even more pronounced in case of beams containing coarse particles. The opposite trends were observed in splitting simulations (see Figure 4b), where the coarse angular aggregates contributed to higher fracture energy of the mortar, while the round aggregates enabled relatively easy crack propagation through the specimens.

You can download the snippet with OOFEM input file here: splittingtest.zip

Created 3/2012 by Václav Nežerka. Acknowledgements belong also to Jan Zeman and Jan Vorel.