Multiscale Heat Transport

Hydrating concrete produces significant amount of hydration heat, which causes several problems in massive concrete elements. Multiscale simulation helped to find an optimal position of cooling pipes and cooling regime on an arch of Opárno bridge, Czech republic. The bridge was built during 2008-2010 with the arches spanning 135 m, see Figures.

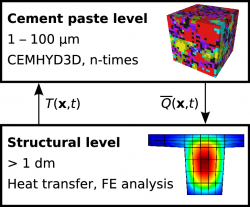

Two computational scales are defined here, see Figure on the right

- Level of cement paste. CEMHYD3D material model predicts the evolution of discrete microstructure on the scale of micrometers and returns liberated heat.

- Structural level. The heat balance equation is solved with finite elements. Several finite elements are grouped together and mapped to one CEMHYD3D instance. Nine OOFEM's instances are used in the simulation.

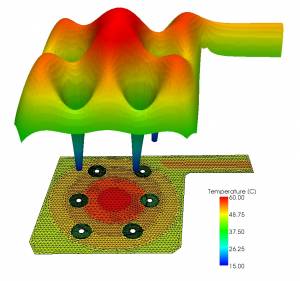

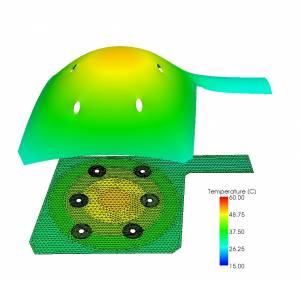

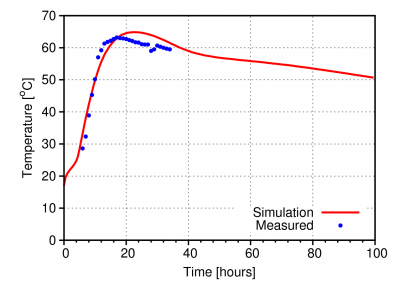

The Figures below show temperature evolution during concrete hardening and induced out-of-plane stress when considering B3 model for concrete creep. The simulation runs on a left symmetric part of the arch cross-section. Optimal position of cooling pipes is apparent. Note that the cooling turns off after several hours which detaches natural Dirichlet's boundary conditions and changes number of equations. The flat bottom subfigure shows the 2D triangular mesh and the assignment of hydration models to groups of finite elements on the cross-section. The right Figure validates the multiscale simulation with the temperature in the core of the cross-section. Temperature remained below 65oC during summer casting, which was found acceptable.

Animation of temperature field during 100 hours after casting. Animation of out-of-plane stress under strain-plane condition.

Created 12/2010 by Vít Šmilauer. Acknowledgements belong also to B. Patzák, Z. Bittnar, J. L. Vítek and Pontex Consulting Engineers, Ltd.